|

| September 16, 2014 | Volume 10 Issue 35 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

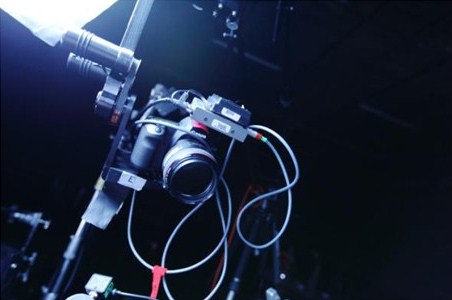

DC motors and careful engineering yield affordable high-performance camera positioning system

Location, location, location. It's not just a real estate mantra. Camera position can make or break a shot.

Feature filmmakers have the luxury of working with dollies and grips and expensive automated technologies to guarantee accuracy and repeatability of camera angles.

Videographers aren't so lucky. With users ranging from bloggers to entertainment channels, to scientists and engineers, the video market presents the same positioning requirements but with only a fraction of the budget. That used to mean performance compromise -- and then camera support system specialist Kessler Crane came along. The company puts the focus on developing affordable positioning systems that still give users the power to create the shots they need.

With the help of sophisticated engineering, plus small DC motors from MICROMO that provide high-end results at a low-end price, Kessler Crane takes economical performance to a whole new level.

"We're actually one of the least-expensive motorized heads on the market in the professional category, and we're doing things that nobody else is doing in terms of features," says Eric Kessler, president and founder of Kessler Crane. "I think the cheapest head we feel outperforms us costs $5,000 to $10,000, and we're doing it for [under $1,900], so we're doing quite a bit with what we have."

Video applications can vary from filming a sporting event to performing time-lapse video of a botany experiment. That means the same positioning system needs to be able to make a lightning-quick 180-degree pan to track a hockey puck speeding over the ice or slowly turn 15 to 20 degrees over a row of plants. It has to provide not only broad range of motion but high dynamic range, while operating with the lowest possible audible noise -- and at the lowest possible price.

Balancing these conflicting demands presented a significant challenge, but the Kessler Crane design team rose to the occasion. The company offers two types of motion systems for video cameras: a pan-tilt unit called the Revolution and a narrow-rail, automatic dolly system known as the CineSlider.

The pan-tilt unit consists of a two-axis system powered by M32P gearmotors from MICROMO's Micro-Drives line. With a 516:1 reduction ratio, the units can provide 4 Nm of torque. To achieve the extreme range of motion, the engineers built the unit with a hollow axel, running the wires up through it. That eliminates windup and allows the Revolution to pan better than 360 degrees in each direction. Velocity varies from one revolution in 3.8 sec to one in 10 min. 40 sec.

The CineSlider features a 4- to 5-in.-wide rail system that mounts on top of a tripod and typically runs 3 to 5 ft. The automatic version combines another M32P gearmotor with Kessler Crane's purpose-built Oracle controller to command the unit in real time by joystick. Velocity varies from 12 in./sec to 12 in./3+ years in time-lapse mode.

No slack

The initial design goal was to produce a system capable of ultra low-speed motion. The problem was that at very low speeds, most motors suffer from cogging. After looking around at their options, the team chose a MICROMO motor with a five-segment commutator rather than a three-segment commutator design, which helped minimize the effects of cogging. That took care of low-end velocity, but the same motor needed to also be able to follow a speeding hockey puck.

Getting sufficient, high-velocity operation remained a challenge until engineers tried briefly and intermittently to overdrive the 12-V motor at 24 V. Because the system gets a boost for only 10 or 15 sec at a time, and only when the load is already moving, the technique does not significantly degrade motor lifetime, especially for the kinds of low duty cycles presented by video applications. "We did some testing to make sure they would survive," says the Kessler design engineer. "[We] ran one motor at 36 volts for an hour. That's equivalent to years of use in this product."

One of the key requirements from the system was backlash-free motion. Although backlash-free motors are available, the price tag was too steep for the type of highly affordable system Kessler envisioned. The team developed a clever alternative. Instead of a single expensive, high-performance motor, they chose a pair of MICROMO's economical DC micro motors, set to run slightly opposed in a master/slave configuration. When properly coupled together, with the aid of fairly sophisticated software, the slave motor pulls the slack from the system. "What we found was that with two economical motors, we could make them perform even better than a high-end, low-backlash motor -- and we got our system to a third of the price by doing it that way," says Kessler.

Source: MICROMO

Published September 2014

Rate this article

View our terms of use and privacy policy